About Us

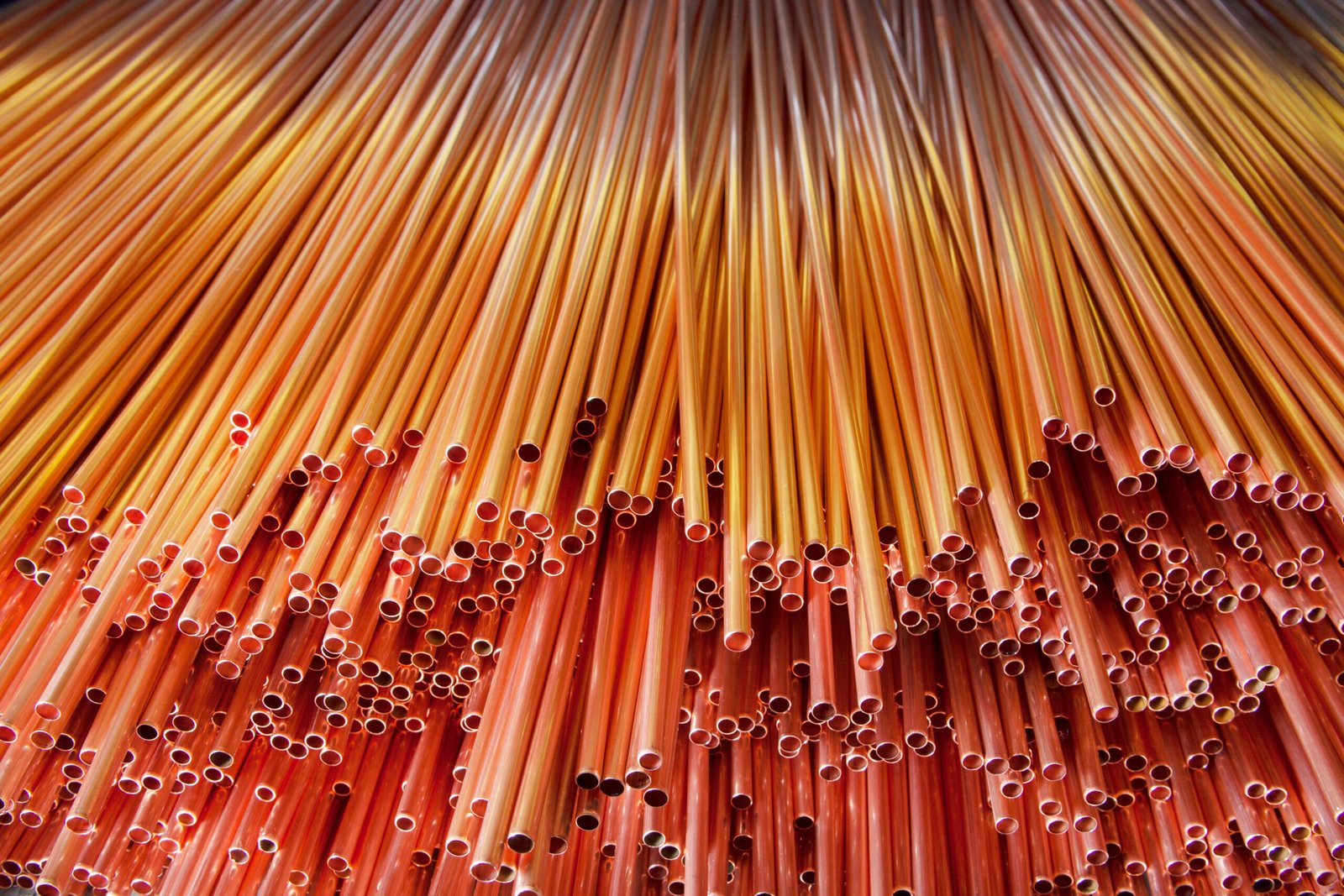

SEAMLESS TUBES

Precision-Engineered Seamless Tubes

Seamless Tubes at Calle are manufactured by the processing of Mother Tubes either by cold drawing or cold Pilger rolling process.

Cold Drawn and Cold Pilgered Tubes

Our Cold Drawn and Cold Pilgered tubes offer superior dimensional accuracy, enhanced surface finish, and exceptional machinability for diverse applications.

Cold Drawn

Cold draw consists of pulling a tube through a die and over a mandrel, reducing the diameter and wall thickness. Tubing is cold-drawn to achieve closer dimensional accuracy, better surface finish, and smaller sizes.

Cold Pilgered

Cold Pilger is a process where a tube is cold-reduced by working it between a rocking set of dies on the outside and a hardened mandrel on the inside. Reduction rates of up to 50 percent are achieved in a single pass. The cold Pilger process yields a tube with a superior surface finish, tight dimensional tolerances, and excellent machine-ability due to the high compressive residual stresses.

Product Range

Comprehensive Product Range and Grades

Product Range, Dimensions, and Compliances

Our diverse product range adheres to precise sizing requirements and meets international standards, ensuring reliability, quality, and performance across applications.

Product

Cu-Ni & Brass Seamless Tubes

Sizing

OD: 6.00mm to 101.6mm, THK: 0.70mm to 6.00mm, Length: Up to 22 Mtr

Standards

ASTM & ASME